sábado, 17 de febrero de 2018

Descubren la mayor mina de oro de la historia de China

Este depósito podría producir oro continuamente y a plena capacidad durante 40 años.

La compañía Shandong Gold Group ha anunciado este martes el hallazgo de la mayor mina de oro de China en la provincia oriental de Shandong, informa 'China Daily'.

Se reporta que el depósito, situado en la región de Laizhou-Zhaoyuan (península de Jiaodong), tiene más de 2 kilómetros de largo y alcanza los 67 metros en su parte más ancha. Debido a sus características geológicas especiales, esta región cuenta con los depósitos de oro más grandes del país.

El valor de la mina

Hasta la fecha, se han detectado 382,58 toneladas de reserva -con un grado medio de oro de 4,52 gramos por tonelada-, pero esta cifra podría aumentar hasta las 550 toneladas a medida que avance la búsqueda en los próximos dos años. Esto se traduce en un valor potencial de 150.000 millones de yuanes (unos 22.000 millones de dólares).

Se reporta que si se procesaran 10 toneladas al día, la mina podría producir oro continuamente y a plena capacidad durante 40 años.

Pulverizing electronic waste is green, clean - and cold

Researchers at Rice University and the Indian Institute of Science have an idea to simplify electronic waste recycling: Crush it into nanodust.

Specifically, they want to make the particles so small that separating different components is relatively simple compared with processes used to recycle electronic junk now.

Chandra Sekhar Tiwary, a postdoctoral researcher at Rice and a researcher at the Indian Institute of Science in Bangalore, uses a low-temperature cryo-mill to pulverize electronic waste - primarily the chips, other electronic components and polymers that make up printed circuit boards (PCBs) - into particles so small that they do not contaminate each other.

Then they can be sorted and reused, he said.

The process is the subject of a Materials Today paper by Tiwary, Rice materials scientist Pulickel Ajayan and Indian Institute professors Kamanio Chattopadhyay and D.P. Mahapatra.

The researchers intend it to replace current processes that involve dumping outdated electronics into landfills, or burning or treating them with chemicals to recover valuable metals and alloys. None are particularly friendly to the environment, Tiwary said.

"In every case, the cycle is one way, and burning or using chemicals takes a lot of energy while still leaving waste," he said. "We propose a system that breaks all of the components - metals, oxides and polymers - into homogenous powders and makes them easy to reuse."

The researchers estimate that so-called e-waste will grow by 33 percent over the next four years, and by 2030 will weigh more than a billion tons. Nearly 80 to 85 percent of often-toxic e-waste ends up in an incinerator or a landfill, Tiwary said, and is the fastest-growing waste stream in the United States, according to the Environmental Protection Agency.

The answer may be scaled-up versions of a cryo-mill designed by the Indian team that, rather than heating them, keeps materials at ultra-low temperatures during crushing.

Cold materials are more brittle and easier to pulverize, Tiwary said. "We take advantage of the physics. When you heat things, they are more likely to combine: You can put metals into polymer, oxides into polymers. That's what high-temperature processing is for, and it makes mixing really easy.

"But in low temperatures, they don't like to mix. The materials' basic properties - their elastic modulus, thermal conductivity and coefficient of thermal expansion - all change. They allow everything to separate really well," he said.

The test subjects in this case were computer mice - or at least their PCB innards. The cryo-mill contained argon gas and a single tool-grade steel ball. A steady stream of liquid nitrogen kept the container at 154 kelvins (minus 182 degrees Fahrenheit).

When shaken, the ball smashes the polymer first, then the metals and then the oxides just long enough to separate the materials into a powder, with particles between 20 and 100 nanometers wide. That can take up to three hours, after which the particles are bathed in water to separate them.

How to Properly Recycle Electronics Avoiding Environment, Human Rights Abuse

How to Properly Recycle Electronics Avoiding Environment, Human Rights Abuse

Not all aging gadgets will be safely dismantled and have their components scrapped or re-used when dropped off at local US recycling centers, according to Basel Action Network (BAN), an environmental nonprofit.

Electronics recycling often involves a complex, multi-step supply chain. Many of the downstream operations are in the developing world, where waste is exported for treatment. Once it arrives for processing, oversight can be minimal.

This can lead to unsafe labor and environmental conditions having a devastating impact on the countries receiving electronics recyclables according to BAN. The ostensibly well-intended act of recycling has the potential to harm workers, their communities, and the environment. BAN suggests that greater transparency in electronics recycling supply chains is one way companies could help.

As part of its long-standing commitment to responsible processing of used electronics, HP is disclosing the names and locations of its recycling vendors.

By bringing transparency to its electronics recycling supply chain, HP seeks to inspire other tech companies, retailers, and distributors to follow suit as well as to acknowledge the work of recycling partners to meet higher expectations. This transparency also helps HP customers feel confident their end-of-life equipment is adequately treated to ensure data and privacy protection.

"HP is disclosing its recycling partners to raise the bar for transparency in our industry and to highlight the high standards we set for those vendors," said Annukka Dickens, HP Director of Human Rights and Supply Chain Responsibility. "We challenge other companies in and outside of the high tech industry to follow our lead and disclose recycler vendor standards and performance, as well as the list of recycling vendors they employ globally."

Ties Back to the Circular Economy

A key part of HP's circular economy strategy is responsible recycling of used electronics, which encompasses industry-leading recycling and reuse standards, a robust recycler audit program, and close engagement with recycling partners.

In addition to transparency in HP recycling programs, they are also reducing resource consumption by reinventing product design to extend the life of products, shifting to service models, and transforming how whole industries design, make, and distribute products through disruptive technologies, such as 3D printing.

The End-of-Life Electronics Challenge

HP knows from experience that recycling responsibly is no small effort. The company is one of high tech's most active recyclers. They have recaptured and recycled over 3.3 billion pounds of computer and printing hardware and 682 million ink and toner cartridges since in the past 30 years.

HP also offers takeback and recycling programs to keep used electronics and printing supplies out of landfills in more than 70 countries and territories through its HP Planet Partners program. It also collaborates with governments and industry stakeholders to promote innovative solutions for managing electronics equipment at the end of its life cycle.

As part of the company's stringent recycling vendor management process, HP requires every specialist vendor to execute environmentally-responsible processing techniques, comply with relevant government regulations, and achieve additional commitments like ethical labor practices and conformance to the Basel Convention, which limits shipment of non-functional electronics between countries.

In addition, vendors must attain third-party certification, such as e-Stewards, R2, or WEEELABEX, where applicable, and must also submit to regular audits.

Collaboration to Ensure Performance

In 2015, HP conducted audits at 58 facilities in 20 countries, including audits to follow-up on previous findings and confirm ongoing commitment to responsible practices and improved performance.

In extreme cases, vendors are not allowed to continue recycling on HP's behalf if they do not work to address nonconformance identified during audits.

"People should know how and where their equipment is recycled. We encourage customers to ask questions about what really happens to the equipment they return," Dickens said.

martes, 6 de febrero de 2018

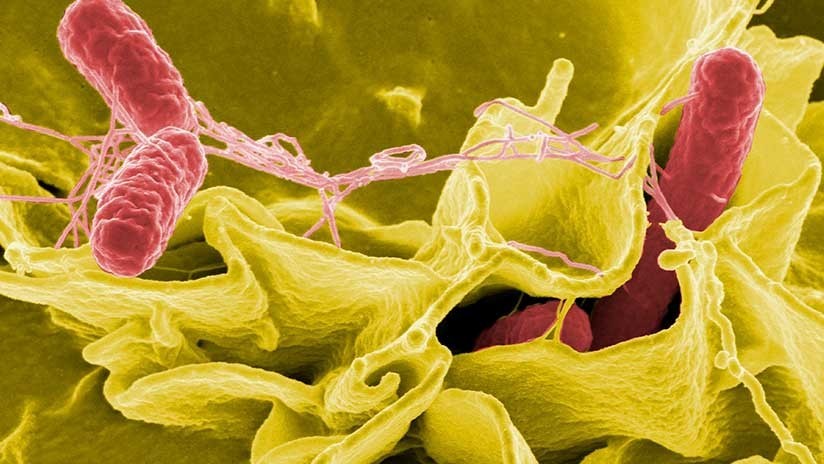

Científicos descubren cómo una bacteria convierte toxinas en oro (FOTO)

pixabay.com / skeeze

En un estudio realizado en el año 2009, expertos alemanes y australianos demostraron que la bacteria C. metallidurans puede producir oro de manera biológica.

Un equipo de científicos alemanes y australianos ha desentrañado los procesos molecurales que tienen lugar en el interior del bacilo C. metallidurans, una bacteria capaz de digerir metales tóxicos y convertirlos en oro. Los investigadores difundieron los resultados en un estudio publicado el pasado miércoles. El equipo científico está formado por expertos de la Universidad Martín Lutero (UML), de Halle-Wittenberg, en Alemania, la Universidad Técnica de Munich y la Universidad de Adelaida, en Australia.

La bacteria C. metallidurans vive principalmente en suelos con alto contenido de metales pesados. Con el paso del tiempo, algunos minerales se descomponen y liberan metales pesados tóxicos e hidrógeno en su entorno. Pero más allá de la prensencia de estos últimos, "las condiciones de vida en esos suelos no son malas. Hay suficiente hidrógeno para conservar energía y casi no hay competencia. Si un organismo opta por sobrevivir aquí, tiene que encontrar una manera de protegerse de estas sustancias tóxicas; la bacteria C. metadillurans lo ha hecho", asegura Dietrich H. Nies, profesor de microbiología molecular en la UML y autor principal del estudio.

El oro se introduce en la bacteria del mismo modo que lo hace el cobre. El cobre es un elemento vital para la bacteria C. metadillurans, pero es tóxico en grandes cantidades. Cuando las partículas de cobre y oro entran en contacto con dicha bacteria, se produce una serie de procesos químicos. Si se hallan ambas en el interior de la bacteria, se suprime la enzima CupA, que es la encargada de expulsar las partículas de cobre, en tanto que los compuestos tóxicos de cobre y oro permanecen en el interior de la célula.

Las bacterias activan entonces la enzima Cop A, la cual transforma los compuestos de ambos metales en formas originalmente díficiles de ser absorbidos, de modo que menos compuestos de cobre y oro entran en el interior de la célula. En consecuencia, se elimina el exceso de cobre, y los compuestos de oro, que son díficiles de absorber, se convierten en pepitas en el área exterior de la célula.

La bacteria C. metallidurans juega un papel fundamental en la formación del llamado oro secundario, que se genera en la naturaleza a raíz de la descomposición de minerales de oro primarios. El estudio realizado por el equipo científico germano-australiano ha proporcionado información relevante sobre el ciclo biogeoquímico del metal precioso. En un estudio realizado en el año 2009, los científicos habían ya demostrado que la bacteria C. metallidurans puede producir oro de manera biológica. Pero desconocían el porqué de este proceso de conversión.